Chlorination systems

Water disinfection is critical to ensure the safety of any potable water supply. Chlorination is a highly effective way to disinfect potable water, and can be dosed into the water as a chlorine gas (Cl2) or as a liquid (Sodium Hypochlorite). The major advantage of chlorine is its residual disinfection effect; it ensures disinfection right up to the point of end use. When water is stored for extended periods, the residual level of free chlorine should be monitored, and topped up as required.

Description

Water disinfection is critical to ensure the safety of any potable water supply. Chlorination is a highly effective way to disinfect potable water, and can be dosed into the water as a chlorine gas (Cl2) or as a liquid (Sodium Hypochlorite). The major advantage of chlorine is its residual disinfection effect; it ensures disinfection right up to the point of end use. When water is stored for extended periods, the residual level of free chlorine should be monitored, and topped up as required.

Disinfection systems are typically either:

- In-Line Systems dosing into a flowing pipeline: Control for inline systems can be flow paced only (simplest) based on water flow rate only with operator selected dose rate; or PID flow feed forward Residual Control (most complex) – taking into account water flow & quality to control dose to an operator selected Residual Chlorine level.

- Reservoir based systems: Working with a reservoir recirculation/mixing system provides the benefit of safe and optimum disinfection control due to the buffering effect of the reservoir volume once initially set up & treated. These systems allow for early indication of dosing issues which if responded to promptly can be rectified without poorly treated water entering distribution/downstream system.

De.mem designs, builds & commissions a comprehensive range of Chlorination disinfection systems for water & waste water applications. The systems are delivered turnkey based on client scope and can include operator training, ongoing maintenance services, operation staff & chemical supply to meet the needs of individual clients. Our Chlorination Systems are based on the following primary methodologies:

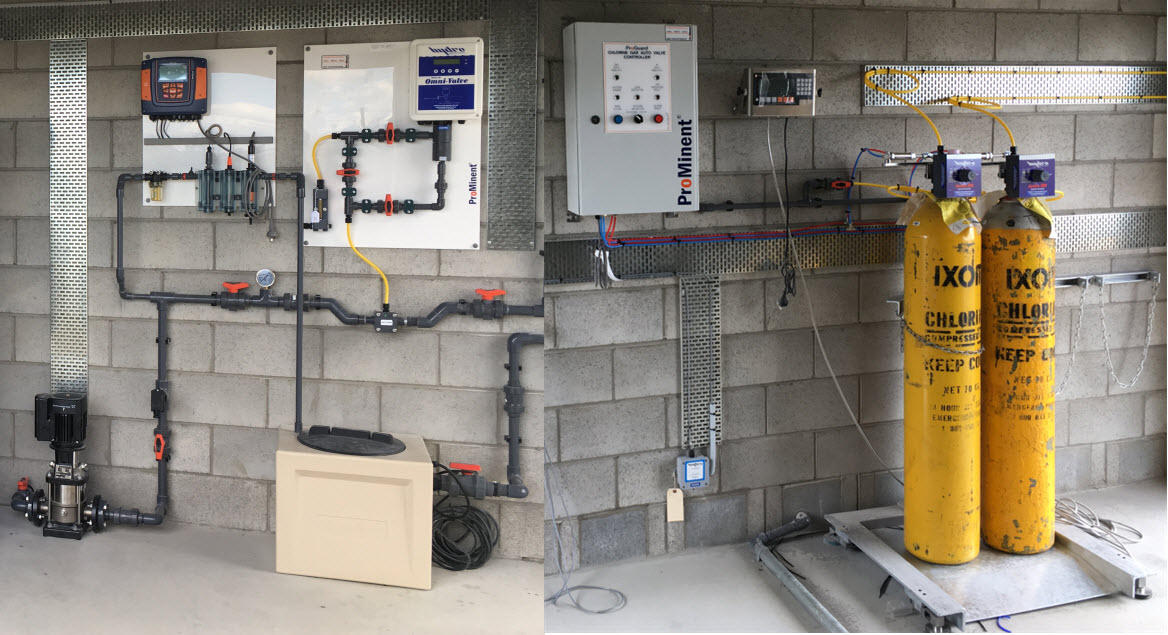

- Chlorine Gas Disinfection (Cl2): De.mem’s Chlorine Gas Disinfection Systems are based on a standard treatment process which includes a recirculation pump to turn over the contents of the potable water storage tank twice in a 24 hour period, an inline chlorine analyser which monitors residual free chlorine and a dosing system to automatically dose chlorine gas as required. The systems are designed to maintain the correct amount of free chlorine in a potable water storage tank, in accordance with Australian Drinking Water Guidelines (ADWG) or other national standards.

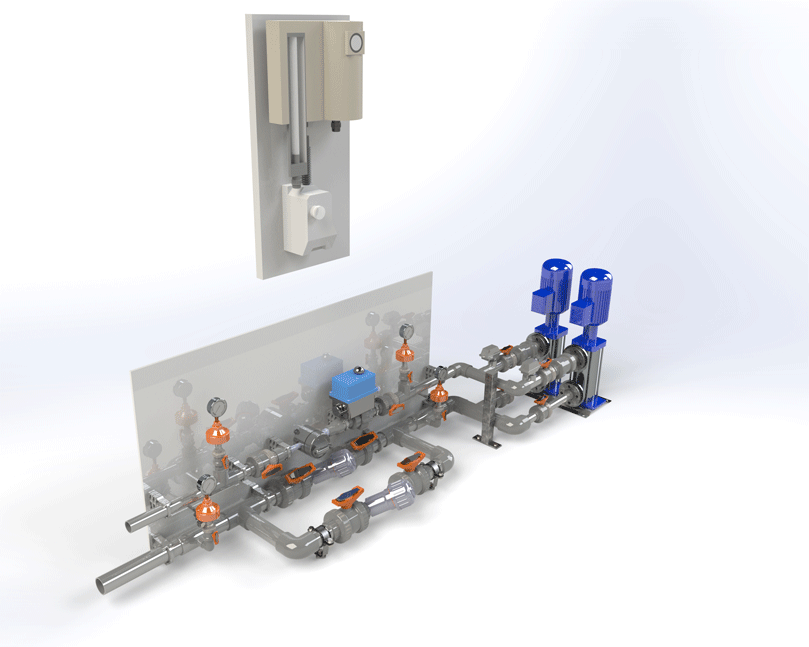

- Sodium Hypochlorite (liquid) Disinfection (NaOCl): mem’s Sodium Hypochlorite Disinfection Systems are based on a standard treatment process which includes a recirculation pump to turn over the contents of the potable water storage tank twice in a 24 hour period, an inline chlorine analyser which monitors residual free chlorine and a dosing pump to automatically dose liquid sodium hypochlorite as required. The systems are designed to automatically maintain the correct amount of free chlorine in a potable water storage tank, in accordance with Australian Drinking Water Guidelines (ADWG) or other national standards.

- Electro-chlorination: De.mem’s Electro-chlorination Systems generate Sodium Hypochlorite (NaOCl) on-site through electro-chlorination. The process can be based on brine solution or brackish/seawater as a source solution. Some of the benefits of De.mem’s Electro-chlorination Systems include low operating costs, on-demand sodium hypochlorite production, no handling or transportation of hazardous materials and easy operation.

De.mem also supplies Chlorine Dioxide (generated on-Site / Point of Injection) systems – typically using Sodium Chlorite (NaClO2) & Hydrochloric Acid (HCl).