Hollow Fibre Forward Osmosis

Forward Osmosis (FO) is an osmotic process that uses a semi-permeable membrane to effect separation of water from dissolved solutes. It works without the application of external, hydraulic pressure. Based on osmotic pressure differences, a draw solute draws water through the membrane until the pressure differences in the two segments are balanced.

Description

Forward Osmosis (FO) is an osmotic process that uses a semi-permeable membrane to effect separation of water from dissolved solutes. It works without the application of external, hydraulic pressure. Based on osmotic pressure differences, a draw solute draws water through the membrane until the pressure differences in the two segments are balanced.

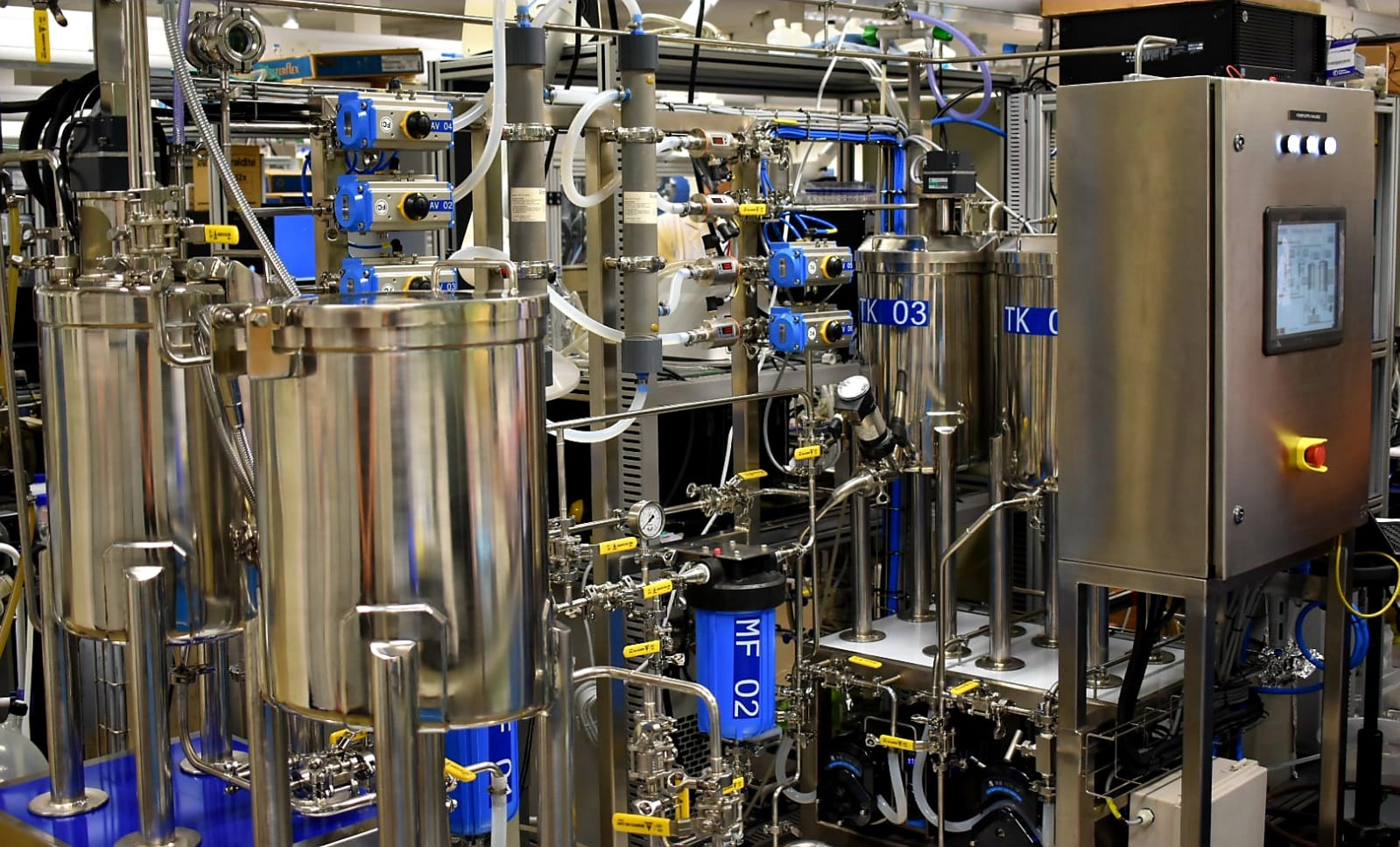

De.mem holds the exclusive, worldwide rights in a new hollow-fibre FO technology originally developed by Nanyang Technological University, Singapore (NTU), for applications in industrial waste water treatment, in particular, the de-watering of reject/concentrate from membrane-based water treatment plants.

While FO has been on the market already mainly as a flat sheet membrane with limited market penetration until today, the hollow fibre technology of De.mem, developed at NTU, Singapore, overcomes certain technical challenges of previous flat sheet FO. It can deliver high flux (=high concentration of feed), low salt back flux (=low draw solution leakage) and is easy to be manufactured and scaled up for higher volume applications.

By using the technology for the specific application covered through the license, De.mem aims to substantially reduce the volume of concentrated waste (“reject” or “concentrate”), which is generated by membrane-based water treatment plants. The disposal of such reject is a key cost factor for the operators of these plants. The removal of just one tonne of concentrate can cost up to A$500.

De.mem has demonstrated that its FO technology can reduce the volumes of reject by up to two thirds, providing substantial cost savings for clients. The technology can be utilised in place of current ‘Zero Liquid Discharge’ processes and evaporators, which are expensive to purchase and operate. This leaves De.mem well positioned to capitalise on a high growth market, which is cited to be worth approximately A$400 million per annum (source: ForwardOsmosis Tech).

The rights in the technology for industrial waste water treatment applications have been sub-licensed to De.mem by Aromatec Pte Ltd, Singapore. Applications in beverage production represent a very large commercial market. They are being pursued by Aromatec, a partner company of De.mem in which De.mem currently holds a 32% stake.

Within beverage production, concentration process are widely used for example for the production of milk powder, coffee, tea, beer or fruit juice concentrate. The De.mem-Aromatec technology provides an alternative for gentle and taste- and nutrients preserving concentration, over evaporation, which is the current state-of-the-art.