Mining

MARKETSMining and mine processing facilities face different water treatment challenges throughout the whole life cycle of operations.Those range from the provision of potable water and the treatment of sewage from mining camps to the generation of process water for as well as the treatment of waste water from the mining operations.

On the waste water side, the mining operators are subject to strict discharge limits imposed by the regulators, which brings along a need for innovative and efficient treatment solutions. Typical mining wastewater will have oil by-products, high turbidity and suspended solids in addition to other contaminants.

De.mem deploys innovative products and solutions that address all of the above. Our customers include many of the leading global mining corporations as well as suppliers and outsourcing providers to the mining sector.

To achieve the above, De.mem deploys all common treatment processes including its proprietary hollow fibre membranes. De.mem can deliver the optimum solution to the customer at competitive cost.

De.mem Products

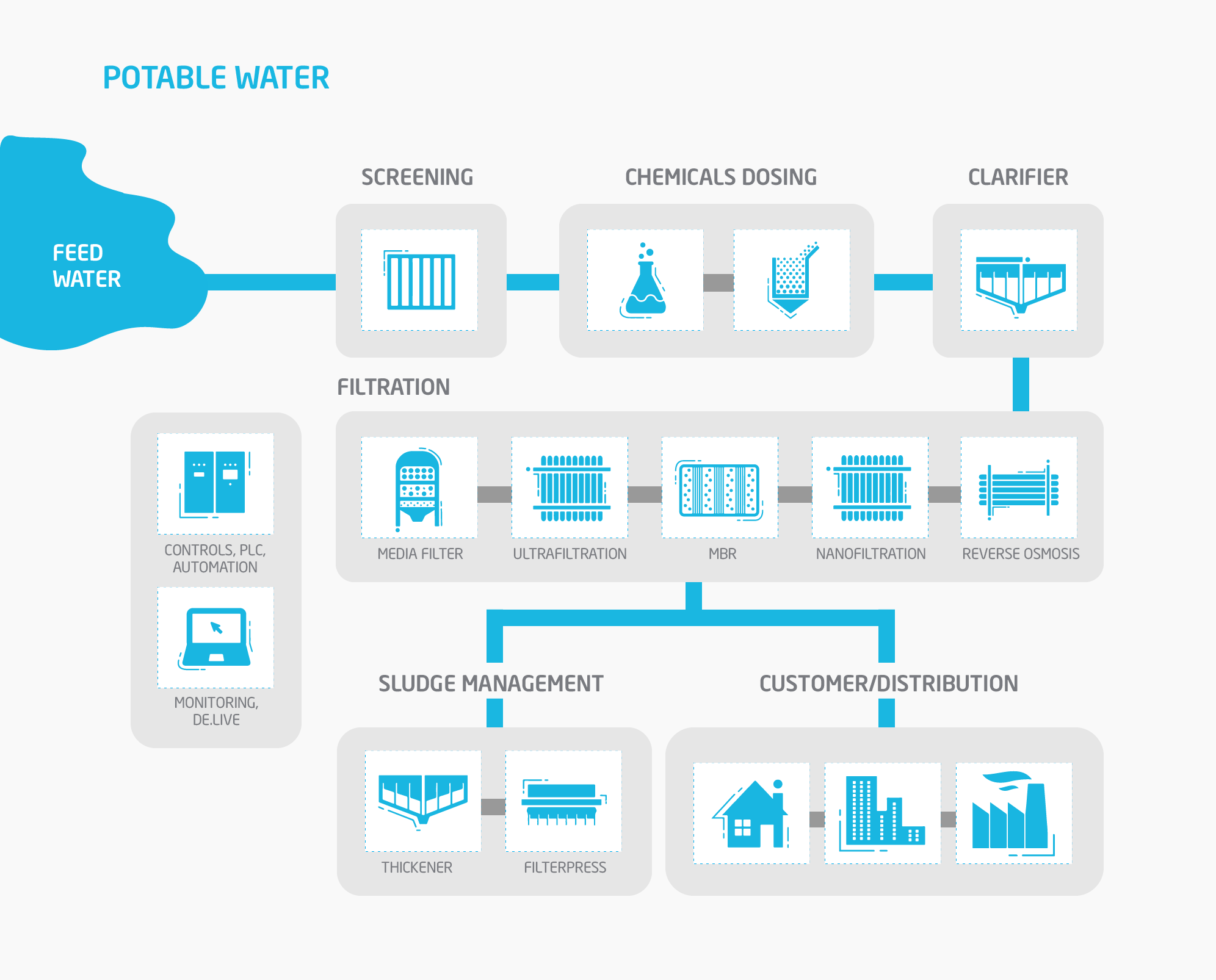

- Potable water treatment (for mining camps)

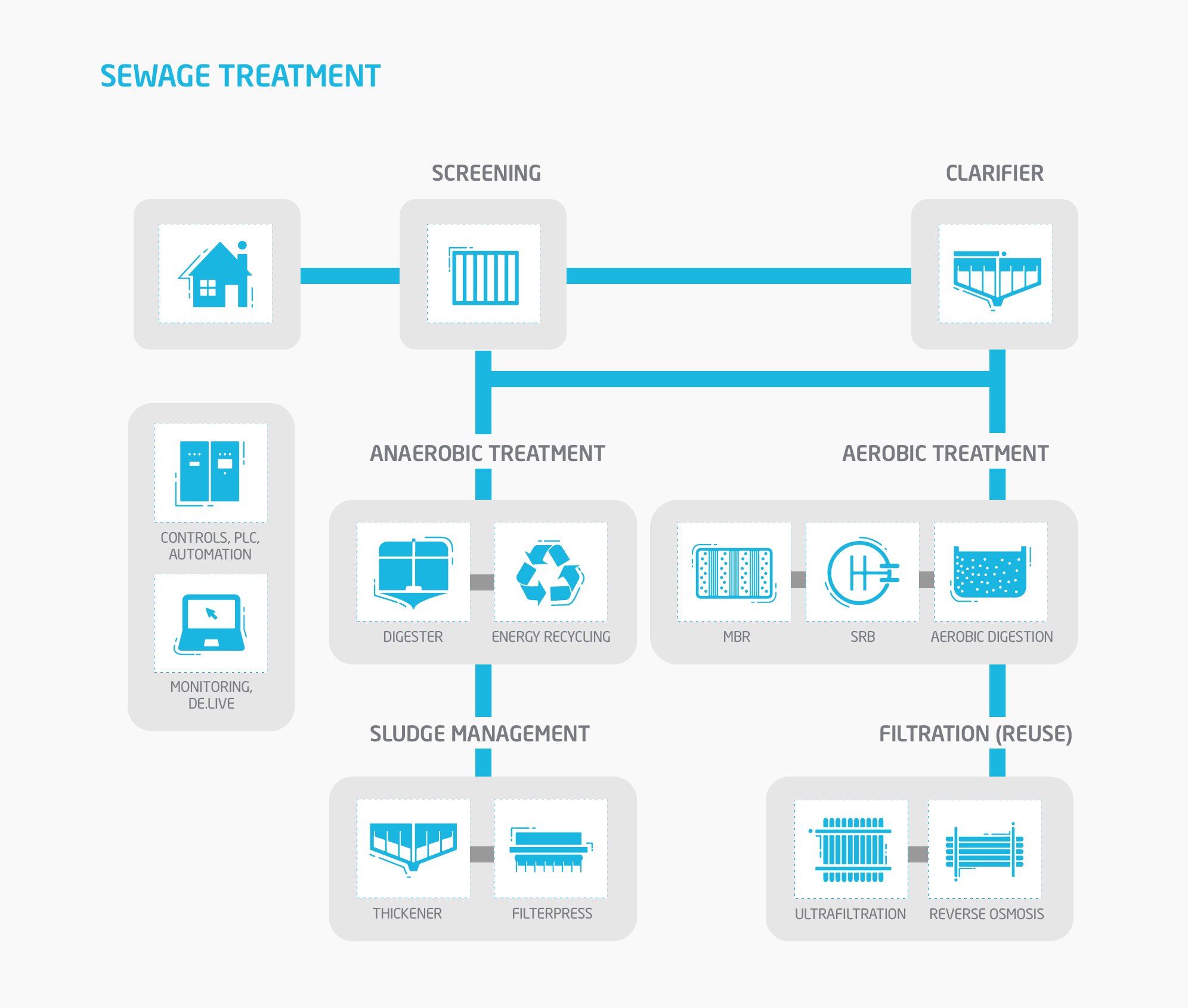

- Sewage treatment (for mining camps)

- Treatment of waste water from mining operations to discharge standards

- Tailings dam remediation

- Membrane based water treatment, such as:

- Reverse Osmosis

- Nanofiltration

- Ultrafiltration

- Media filtration

- Membrane Bioreactors (MBRs)

- Chlorination systems

- Chemical dosing systems

- Automation

- PLC

- De.live remote monitoring system

- Other, such as

- Chemicals

- Disinfection, screening, sludge management, aeration & evaporation systems

- Water softening systems

- Valving with pneumatic or electric control

- Customized processes and systems for specific client needs

De.mem Services

- Treatability studies

- Pilot studies

- Design and construction of systems, system installation, commissioning, follow up services and operations

- Training of operators and technical staff

- Build, Own, Operate schemes (“BOO”)

- Consulting services

- Client-tailored research & development services

Reference Projects

-

Water Treatment Site Management, Mining Camp, Australia

De.mem designed, built and commissioned the drinking water and sewage treatment facilities for a mining camp in Queensland, Australia.

-

Water Treatment Site Management, Island Resort, Australia

De.mem manages the water and waste water treatment requirements for a holiday resort on a remote island in Australia

-

Waste Water Treatment BOO, Food & Beverage Industry, Singapore

De.mem developed a waste water treatment and recycling system for the Singapore factory of a multinational